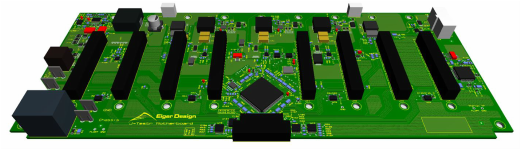

J-Testr System Motherboard

Features24V and 48V input supply compatible up to 240W

Input supply voltage and current monitoring 2.5V, 3.3V and 5V 6A capable high efficiency supplies System supply voltage and current monitoring Ultra Simple Ethernet Interface to J-Testr Parallel Bus Intergrated JTAG to J-Testr Parallel Bus converter (For JTAG systems) Fully integrated JTAG TDO/TDI bypass mechanism Two Fan speed controllers with rpm monitoring Support for in-system firmware update High Speed Peripheral Support signalling J-Safe safety features Input supply filtering |

About

The Motherboard/System is the heart of the J-Testr functional test system and provides all the required power, communication and signals for up to 8 plug-able peripheral cards.

The motherboard can accept either 24V (10A) or 48V (5A) DC power input which is used to generate all the system supplies and is distributed throughout the J-Testr system. Low voltage system supplies generate 2.5V, 3V3 and 5V capable of 6 amps each which are also distributed to all peripheral cards.

All supplies of the motherboard are high efficiency enabling them to be very compact and save on total system power.

Every system supply, including the power input, has voltage and current monitoring, with fully J-Safe support, enabling the user to verify the test system is running within the expected normal operating limits.

The system motherboard logic allows the J-Testr to be controlled from either a Ethernet port or direct control via JTAG giving total software flexibility. Both communications methods have a simple protocol that is easily adapted to any software platform with either a Socket or JTAG interface.

Two programmable linear fan controllers allow the user to adjust the Fan speeds as required. Fan override circuitry will override user fan setting if critical parts of the system get too hot. This allows the user to ramp fan speeds when they know high power demands are going to be required, keeping the system cool and internal measurement circuitry accurate. Alternatively, the user can reduce fan speed under low load situations to reduce ambient noise and improve operator comfort.

As cooling is an essential part of any test system and with ‘Test in Mind’ the J-Testr system allows the user to read the fans speeds to verify their correct operation before or during a test.

The motherboard can accept either 24V (10A) or 48V (5A) DC power input which is used to generate all the system supplies and is distributed throughout the J-Testr system. Low voltage system supplies generate 2.5V, 3V3 and 5V capable of 6 amps each which are also distributed to all peripheral cards.

All supplies of the motherboard are high efficiency enabling them to be very compact and save on total system power.

Every system supply, including the power input, has voltage and current monitoring, with fully J-Safe support, enabling the user to verify the test system is running within the expected normal operating limits.

The system motherboard logic allows the J-Testr to be controlled from either a Ethernet port or direct control via JTAG giving total software flexibility. Both communications methods have a simple protocol that is easily adapted to any software platform with either a Socket or JTAG interface.

Two programmable linear fan controllers allow the user to adjust the Fan speeds as required. Fan override circuitry will override user fan setting if critical parts of the system get too hot. This allows the user to ramp fan speeds when they know high power demands are going to be required, keeping the system cool and internal measurement circuitry accurate. Alternatively, the user can reduce fan speed under low load situations to reduce ambient noise and improve operator comfort.

As cooling is an essential part of any test system and with ‘Test in Mind’ the J-Testr system allows the user to read the fans speeds to verify their correct operation before or during a test.