|

J-Testr NextGen Systems are designed specifically for companies that are looking for a full featured complete fixture based benchtop 'functional test solution' that enables them to get 'up and running' straight away whilst at the same time taking advantage of the advanced features and protection offered by the seamlessly integrated

J-Testr Core. |

- Off the shelf complete function test system solutions based on the J-Testr Core

- Compact proven ‘All in one’ solutions with modular configurations available in two sizes (Midi and Max)

- J-Safe UUT protection built in with safety Interlocks and advance Self-Test options

- Common architecture with 2 size options (Midi and Max) depending on maximum UUT size.

- Seperate dedicated UUT power sources and loads plus multiple system supplies

- Exchangeable units for both ‘Bed of Nails’ and ‘Manual Plugging’ to suit UUT volumes

- JTAG Compatible Low voltage (up to 512) and High Voltage (up to 64) IOs

- High-speed IOs with Triggering, signal monitoring and pattern generation (up to 64)

- Configurable User IOs with UART, I2C, SPI, PWM, Timer, GoSafe functions (up to 64)

- Precision fully differential (or Single Ended) ADC (up to 256) and DAC lines (up to 64)

- Flexible Ethernet and USB interfaces available internally and externally.

- Optional DUAL Channel Oscilloscope with Signal Generator and Switch Matrix (Standard on Max)

- Optional DUAL CAN, DUAL RS422/485 communications

- Optional DUAL ARINC429 communications

- Options for seamless JTAG system, Flash programmers’ integrations

- Options for RF measurement and RF Exchangeable for IOT Devices

- Ergonomic design with easy customization with friendly accessories.

- User friendly microprocessor like register interface with open source drivers

|

Test Straight Out Of The Box, No hassle

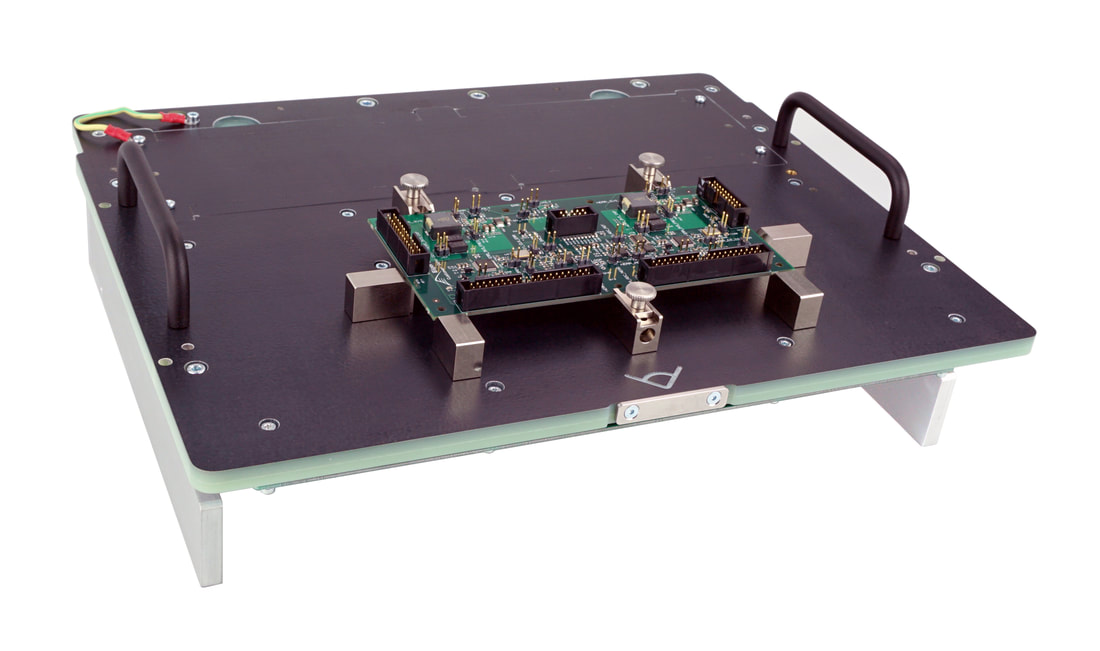

J-Testr NextGen wrap all J-Testr Core test resources into a complete highly compact (465mm x 500mm) complete functional test system with unparalleled safety features. Designed to test your printed circuit boards assemblies (PCBAs) in a complete, cost efficient and safe manner regardless of the production volumes. Available in two sizes, Midi and Max, the NextGen platform is designed to perfectly accommodate your companies UUTs test needs. All J-Testr NextGen systems are reusable for multiple UUTs due to its flexible cartridge-style ‘Exchangeable’ concept that provides the mechanical and electrical UUT interfaces. |

|

Exchangeable Units For Easy & Rapid Changeover

All NextGen system use exchangeable units that can be easily customized for your UUTs. These exchangeable units are easily taken "in and out" of the test system within a few seconds with stimulation and measurement signals connected via a reliable mass interconnect 'Pylon' interface at the rear. The NextGen supports both ‘low cost’ manual plugging, using the 'Manual Plug exchangeable', as well as more conventional ‘bed-of-nails’ connections, using the 'Bed of Nails exchangeable' to the UUT allow low volume UUTs to be tested on the same test system as higher volume designs. |

|

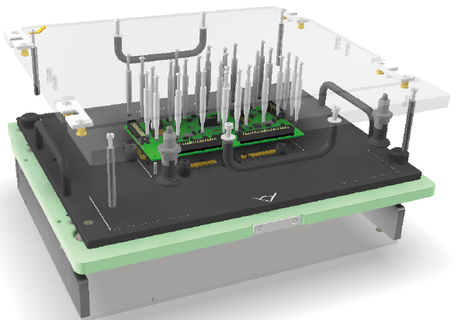

Prototype Test Made Simple

A unique ‘Prototype Exchangeable Unit’ allows NextGen test systems system to be used immediately upon receiving the first/prototype UUT with NO tooling. This allows test developers, or even R+D teams, to utilise the test system from a very early stage in the product development cycle. Test development and design verification can be done before committing to ‘Bed of Nails’ tooling, allowing developed test code/circuitry to be easily reused and passed forward to the final production test, saving significant time and resource. Using our J-Mount, the UUT can be held securely with quick and easy insertion, lock and release, without damage to components or solder joints. |

|

True Self Test Options

The J-Testr NextGen has an option for a 'Self-Test exchangeable' that measures all possible signal interconnects using analogue measurements and electrical loading to help determine open circuits, short circuits and ‘higher than normal’ resistance connections. This allows the operator to successfully validate the test system, and all its interconnection, and eliminate it from any problems shooting if any problems where to occur. The operator can then focus on the exchangeable that can be easily transported to a service location for further investigations |

|

Expandable And Versatile

Utilising the J-Testr core, J-Testr Peripheral Cards options add modular measurement and/or stimulation functions to the J-Testr NextGen systems. Likewise, integration options such as USB/Ethernet, JTAG Boundary Scan and LED analyser integration allow the J-Testr NextGen to perfectly match your UUT requirements. With two size option, Midi and Max, the right system can be selected for your companies UUT typical dimensions. Also, with identical system architectures migration between Midi and Max systems is possible if future UUTs grow above the size of the smaller Midi solution. Either way your investment is safe. |

|

Easy Customization

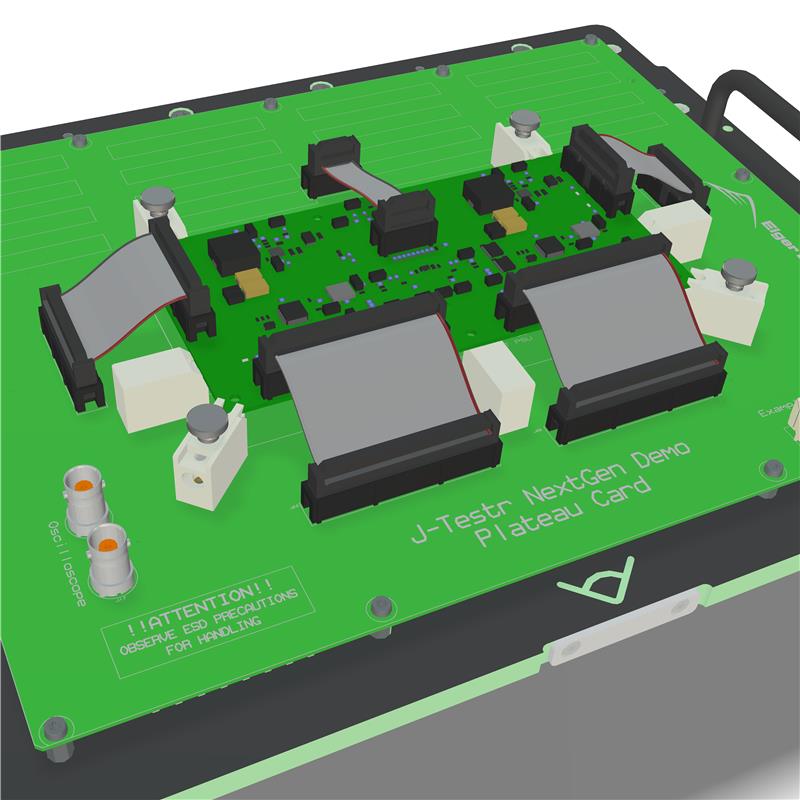

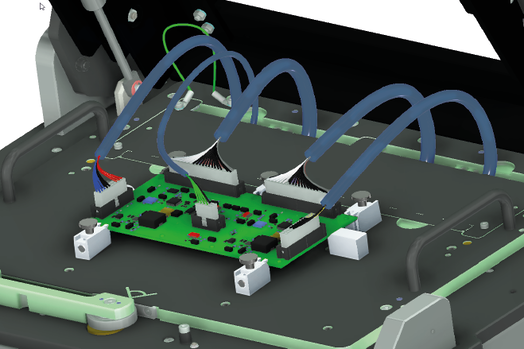

The NextGen system have been designed to make the customization of exchangeable as efficient as possible using common PCB templates to allow transition from the NextGen stimulation/measurement signals to the UUT. These PCB templates allow the signals to be either routed to connectors, for manual plugging of the UUT, or to double sided fixture pins, for Bed-of-nail fixture solutions. This connection architecture, with the addition of the available switched system supplies, allows local electronics, such as buffers and multiplexers, to be added to the PCB interconnect further expanding flexibly. Customisation can be made by the customer or via consultancy from Eiger Design or one of our integration partners. Whichever way is chosen , Eiger Design support and detailed documentations will help to make the process hassle free. |

Real life 3D design images show the same UUT being customised in bed of Nail Exchangeable, for 'high' volume production, Manual plug exchangeable, for 'mid to low' volumes and prototype exchangeable for test development or even low volume production

|

3rd Party Integration

3rd Party integrations are critical to allow customers to expand their functional test environment to suit their UUTs. J-Testr allows for such integration with space inside and on the back of the test system in the form of a bolt on "backpack". Dedicated impedance controlled cabling to and from the UUT exchangeable is provided to allow routing of the required signals. Common examples ares JTAG system such as those available from XJTAG, Geopel and JTAG Tech, High speed ISP programmers from Segger, Algocraft, SMH and others. |