NextGen Customization

Customization is one of the most important part of any functional test system, it is required to make the customers UUT connect back to the test system and mount the UUT securely. Customization is often the part of functional testing, or any other kind of testing, that is the greatest concern to companies. Different companies will have different views on how a UUT should be tested depending on volumes, market segment and UUT value.

A good test system allows for multiple customizations options to suit different types of UUT devices and more importantly different production volumes. An example is the high-volume boards and high value boards (medical/automotive/military /aerospace) will often select to use bed-of-nails fixturing to mount their UUTs and connect back to the test system with pins (nails). Smaller volumes UUTs, or companies with smaller budgets, often cannot justify the cost of bed-of-nail and require cheaper options.

As function test is always made with powered up UUTs, customizations often need additional electronics added to satisfy special UUT functions and/or add local buffering or multiplexing close to the UUT to improve signal integrity issues and reduce interconnects.

Eiger Design J-Testr solutions are provided with all information required for customers to make their own customizations* and includes a free check service to customer with a valid maintenance contact. Alternatively, Eiger Design can provide a full or partial customization service to a customer’s test specification.

*Not including ‘bed of Nails’ fixturing

A good test system allows for multiple customizations options to suit different types of UUT devices and more importantly different production volumes. An example is the high-volume boards and high value boards (medical/automotive/military /aerospace) will often select to use bed-of-nails fixturing to mount their UUTs and connect back to the test system with pins (nails). Smaller volumes UUTs, or companies with smaller budgets, often cannot justify the cost of bed-of-nail and require cheaper options.

As function test is always made with powered up UUTs, customizations often need additional electronics added to satisfy special UUT functions and/or add local buffering or multiplexing close to the UUT to improve signal integrity issues and reduce interconnects.

Eiger Design J-Testr solutions are provided with all information required for customers to make their own customizations* and includes a free check service to customer with a valid maintenance contact. Alternatively, Eiger Design can provide a full or partial customization service to a customer’s test specification.

*Not including ‘bed of Nails’ fixturing

J-Test Core Customization (Interposer)

|

The J-Testr Core allows for a customized interposer card (PCB) that is designed to route the stimulation/measurement signals to connectors required to interface to the UUT. When the J-Testr Core is used in fixture applications, the interposer is used to route signals to connectors that further cable to the fixture mass connection interface. In some cases, UUTs can plug directly to the J-Testr Core interposer thus eliminating all cables, such examples are UUT with edge connectors or mezzanine connectors.

As the interposer is a standard PCB it allows for extra electronics to be fitted as per the requirements of the UUT or the test system. Such electronics could be buffers, dividers, filters, multiplexers, relays, etc. Note: J-Testr NexGen systems do not need a customized Interposer as they include a predesigned Generic Test Interposer (GTI) that then cable to the NextGen fixture mass interconnect interface. |

J-Testr NextGen Customization

The J-Testr NextGen offers multiple customization options, all of which are made in the exchangeable units that connect in and out of the main NextGen system.

|

Prototype Exchangeable

The prototype exchangeable is preliminarily designed to be used as a re-usable prototyping platform that allows the NexGen test system to be used from a very early stage of test development, as well as design verification, before committing to other more expensive implementations. However, for cost sensitive application, this exchangeable can be used deployed for simple UUTs with limited interconnects. The prototype kits have access to all pylon stimulations/measurements via solder points (or 40-way headers) and includes a through hole (TH) prototyping area with some uncommitted SMT resources for local electronics if required. |

|

Manual Plug Exchangeable

The manual plug exchangeable provides a mechanical platform for UUT that will interfaced using manual plugged cables. The unique platform has been designed to offer near endless customization possibilities that will suit any PCB that fits withing the systems usable area. The exchangeable consists of a flat ESD safe surface, with multiple mounting holes, and a ESD safe ‘removable lid’ that allows cables to be passed from the lower section to the outer flat surface where the UUT is mounted. The low section has amble space for other devices that maybe required for functional testing such as low-cost ISP programmers, LED analyzers or any other special UUT specific hardware device (e.g. high-speed frame grabbers). Multiple stimulation/measurement routing options are possible, however common methods are described below: |

|

Plateau Card Only

A plateau card PCB is fitted to the outer surface with stimulation/measurement signals connected directly back to the pylons. The plateau card mounts the UUT, using J-Mounts or alternative mounting mechanisms, and contain the required cabling connectors to interface the UUT back to the stimulation/measurement signals. As the plateau card is a standard PCB it allows for extra electronics to be fitted as per the requirements of the UUT or the test system. Such electronics could be buffers, dividers, filters, multiplexers, relays, etc. |

|

Connection Card Only

A connection card PCB is fitted in the lower section with stimulation/measurement signals connected directly back to the pylons and routed to suitable connectors to interface the UUT. The UUT is mounted directly to the outer flat surface, using J-Mounts or alternative mounting mechanisms, and connected back to the connection card via cabling. As the connection card is a standard PCB it allows for extra electronics to be fitted as per the requirements of the UUT or the test system. Such electronics could be buffers, dividers, filters, multiplexers, relays, etc. |

|

Connection Card and Plateau Card

In some customizations both a connection card and a plateau card can be used, this is often used for UUTs that can plug directly to the plateau card such as for UUTs with edge connectors or mezzanine type connectors. |

|

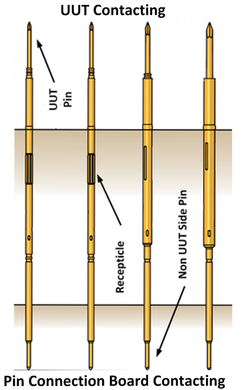

Bed of Nails Exchangeable

Bed-of Nails fixturing has been around forever and is what is typical though about when discussing functional testing. Bed-of Nails is for applications with high interconnects, internal test points, high volumes and/or high value. In the NextGen bed-of-nails exchangeable the connection to the pins are made with a customized ‘Connection Card’ that takes the stimulation/measurement signals from the ‘Pylon’ mass interconnect and routes them to the UUT using double sided pin. More traditional ‘wire-wrap’ techniques are also possible with the bed-of-nails exchangeable; however, they are not recommended due to their poor signal integrity and lower reliability. |

|

The bed-of-nails exchangeable supports lower and upper pinning and has amble space, in the lower section, for other devices that maybe required for functional testing such as low-cost ISP programmers, LED analyzers or any other special UUT specific hardware device (e.g. high-speed frame grabbers).

As the connection card is a standard PCB it allows for extra electronics to be fitted as per the requirements of the UUT. Such electronics could be buffers, dividers, filters, multiplexers, relays, etc or even interfaces to locally mounted LED analyzers and ISP programmers. A full bed of nails customization service is available from Eiger Design or one of Eiger Design integration partners. |